Transformers these days are different than 50 years ago some how they manage to operate fine with a few turns of wire in the primary coil on 120 VAC.

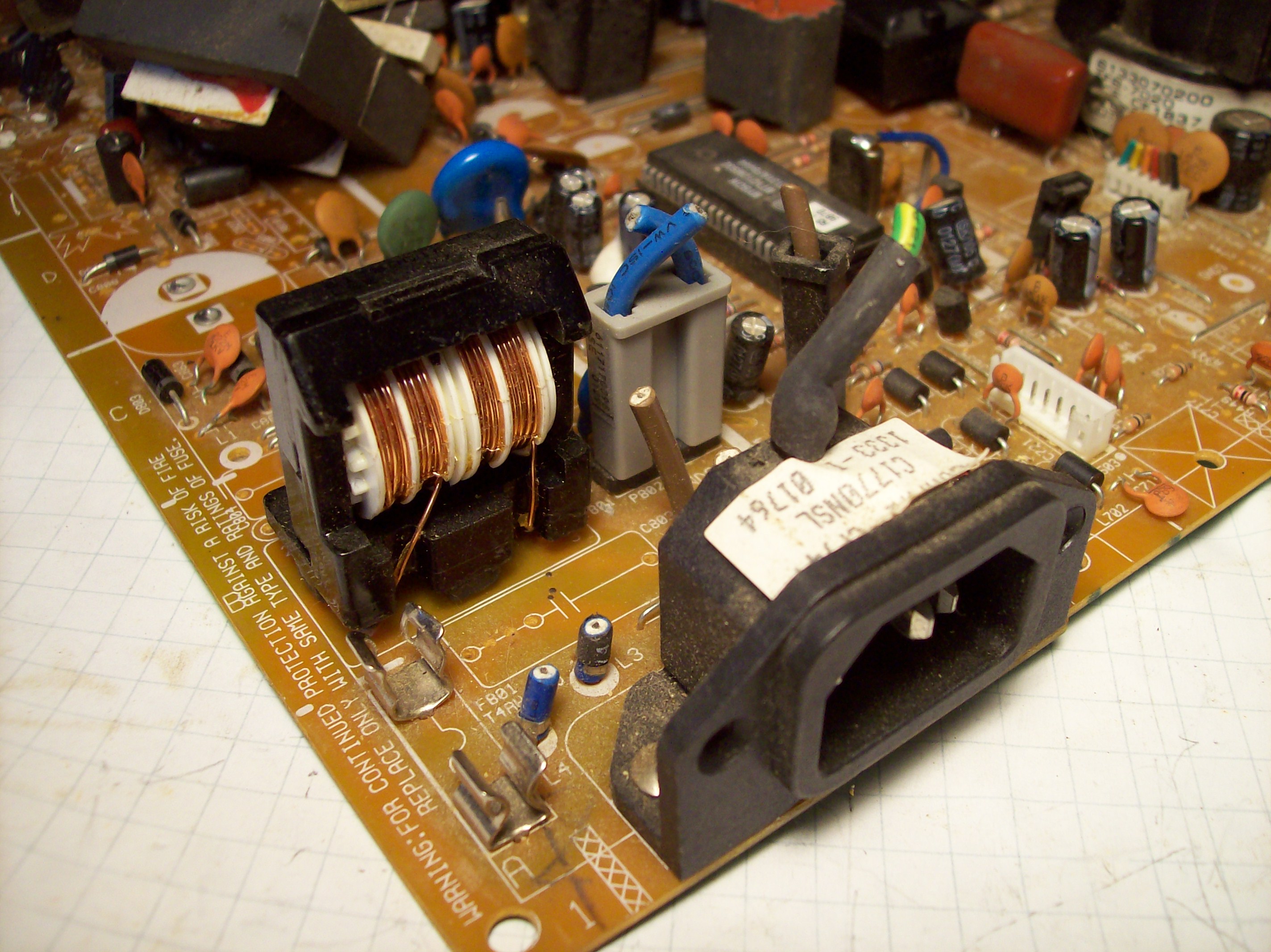

I don't understand the circuits most TV circuit boards are low voltage. First picture transformer steps 120vac down to 100vac ?

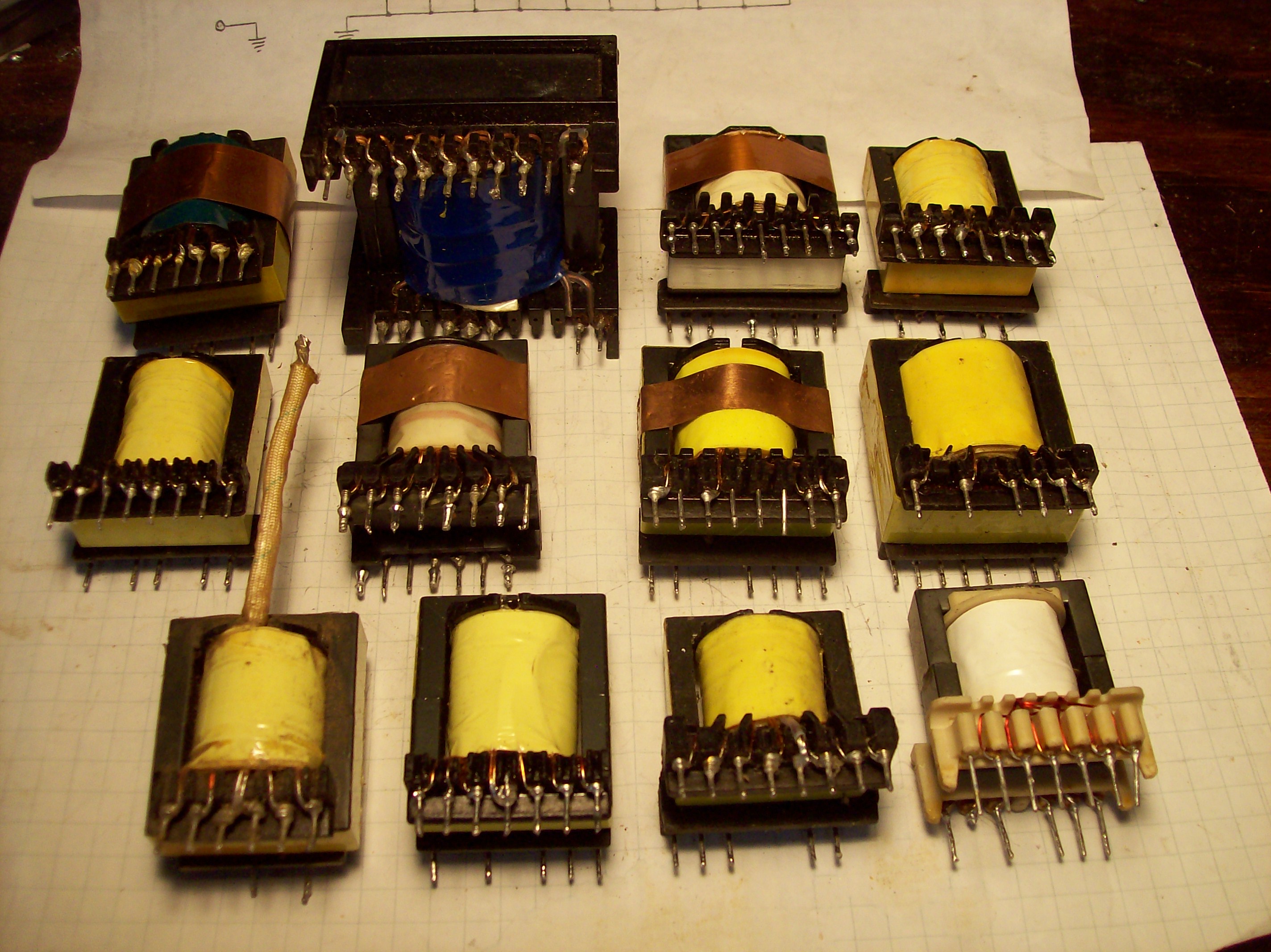

Many of the 4 wire transformers are step down or 1 to 1 ratio, 5 wires 1 coil has center tap on secondary coil.

Multi wire transformers have 4 to 7 coils and I am not sure why I removed these from PC board with out examining the circuit to see what they do.

I have experimented with these newer transformers in the past I think it is interesting the 120 vac primary coil has about 75% less primary coil turns than transformers had 50 years ago and they do not over heat.

Today I needed a 120vac to 12vac transformer the 120vac transformer in my Bridgeport mill burned up in the digital read out. Physical size of old transformer is about 100 watts so I used a variac and amp meter to put 120 vac on each transformer 1 by 1 looking for a 12vac output. As far at the physical size of the newer transformers I have no clue what physical size is 100 watts? I wonder since new transformers have less wire maybe physical size can be smaller to = 100 watts.

It was a challenge to find the correct transformer and to play it safe once I got it figured out I left it ON all day to make sure it did not over heat and burn up. This morning I connected it to the digital read out and it works good. I soldered several windings in series & in phase to finally get 1 output winding almost 12vac.

Some transformers have a copper strap around them, I read once what that does but now I have forgotten?

I don't understand the circuits most TV circuit boards are low voltage. First picture transformer steps 120vac down to 100vac ?

Many of the 4 wire transformers are step down or 1 to 1 ratio, 5 wires 1 coil has center tap on secondary coil.

Multi wire transformers have 4 to 7 coils and I am not sure why I removed these from PC board with out examining the circuit to see what they do.

I have experimented with these newer transformers in the past I think it is interesting the 120 vac primary coil has about 75% less primary coil turns than transformers had 50 years ago and they do not over heat.

Today I needed a 120vac to 12vac transformer the 120vac transformer in my Bridgeport mill burned up in the digital read out. Physical size of old transformer is about 100 watts so I used a variac and amp meter to put 120 vac on each transformer 1 by 1 looking for a 12vac output. As far at the physical size of the newer transformers I have no clue what physical size is 100 watts? I wonder since new transformers have less wire maybe physical size can be smaller to = 100 watts.

It was a challenge to find the correct transformer and to play it safe once I got it figured out I left it ON all day to make sure it did not over heat and burn up. This morning I connected it to the digital read out and it works good. I soldered several windings in series & in phase to finally get 1 output winding almost 12vac.

Some transformers have a copper strap around them, I read once what that does but now I have forgotten?

Last edited: