Rave0035

Member

Hi All! Electronics hobbyist here. I've been at the hobby for about 4 years, and have primarily worked with older audio circuits (tube radios, instrument amplifiers, phonographs, etc). I've mostly done troubleshooting and repair - only a few scratch builds under my belt, so I'm still pretty green when it comes to theory and circuit design. I'm hoping you can help me learn!!

A friend of mine recently picked up a 15 amp 3M Thermofax transparency maker for next to nothing, and asked me to give it a once over. It's cleaned up nicely, and I've got it working, but I've found that the bulbs for this particular model are almost impossible to find and change hands for about $275. He wants to use this professionally, so not having replacement bulbs on hand isn't an option... and at that price, he would be better off buying a different 40 year-old Thermofax every time he needed a new bulb.

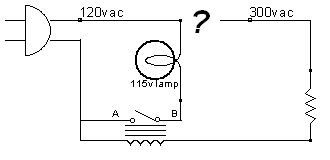

Long story short, I'd like to convert this unit to use the more common 1350watt bulbs from a 12 amp machine, but don't really know where to start to drop the current sufficiently to keep from exploding bulbs or burning his place down.

I have not been able to get my hands on a circuit diagram for this model yet, but I'm still looking. My questions are:

1) What characteristics of the circuit do I need to know to understand what modifications to make?

2) Is this truly as simple as wiring some high-wattage resistors in series with the bulb, or am I fooling myself?

3) Does anybody have a schematic for this laying around? It's not a complex circuit, but I'd still like diagram to stare at.

It's not a complex circuit, but I'd still like diagram to stare at.

Thanks in advance for the help. I really want to learn as I go here!

-Mike, St Paul MN

A friend of mine recently picked up a 15 amp 3M Thermofax transparency maker for next to nothing, and asked me to give it a once over. It's cleaned up nicely, and I've got it working, but I've found that the bulbs for this particular model are almost impossible to find and change hands for about $275. He wants to use this professionally, so not having replacement bulbs on hand isn't an option... and at that price, he would be better off buying a different 40 year-old Thermofax every time he needed a new bulb.

Long story short, I'd like to convert this unit to use the more common 1350watt bulbs from a 12 amp machine, but don't really know where to start to drop the current sufficiently to keep from exploding bulbs or burning his place down.

I have not been able to get my hands on a circuit diagram for this model yet, but I'm still looking. My questions are:

1) What characteristics of the circuit do I need to know to understand what modifications to make?

2) Is this truly as simple as wiring some high-wattage resistors in series with the bulb, or am I fooling myself?

3) Does anybody have a schematic for this laying around?

Thanks in advance for the help. I really want to learn as I go here!

-Mike, St Paul MN