pasanlaksiri

Member

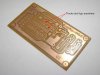

This is just another clock project. The processor that I am using here is PIC16F628A. Clock timing is very accurate thanks to RomanBlack Zero-error 1 second timer algorithm.

Link1>> Zero-error 1 second timing algorithm

Link2 >> https://www.electro-tech-online.com/threads/zezj-zero-error-zero-jitter-period-algorithm.100299/

Nothing much to say about the project so here it is

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed**

PCB Arts

**broken link removed** ***broken link removed**

Silk Screen Layouts

Controle Board BOTTOM

Controle_Board_TOP

SSD_Board_BOTTOM

SSD_Board_TOP

Firmware

Link1>> Zero-error 1 second timing algorithm

Link2 >> https://www.electro-tech-online.com/threads/zezj-zero-error-zero-jitter-period-algorithm.100299/

Nothing much to say about the project so here it is

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed** **broken link removed** **broken link removed** **broken link removed**

**broken link removed**

PCB Arts

**broken link removed** ***broken link removed**

Silk Screen Layouts

Controle Board BOTTOM

Code:

http://www.4shared.com/file/236695715/97e5185a/Controle_Board_BOTTOM.htmlControle_Board_BOTTOM.html

Code:

http://www.4shared.com/file/236695744/9d95dc89/Controle_Board_TOP.html

Code:

http://www.4shared.com/file/236695925/b6566693/SSD_Board_BOTTOM.html

Code:

http://www.4shared.com/file/236696025/ab32f2f2/SSD_Board_TOP.htmlFirmware

Code:

http://www.4shared.com/file/236744326/a9b8c28e/GT_mini_Clock_hex.html

Last edited: