BGAmodz

Member

Hello everyone

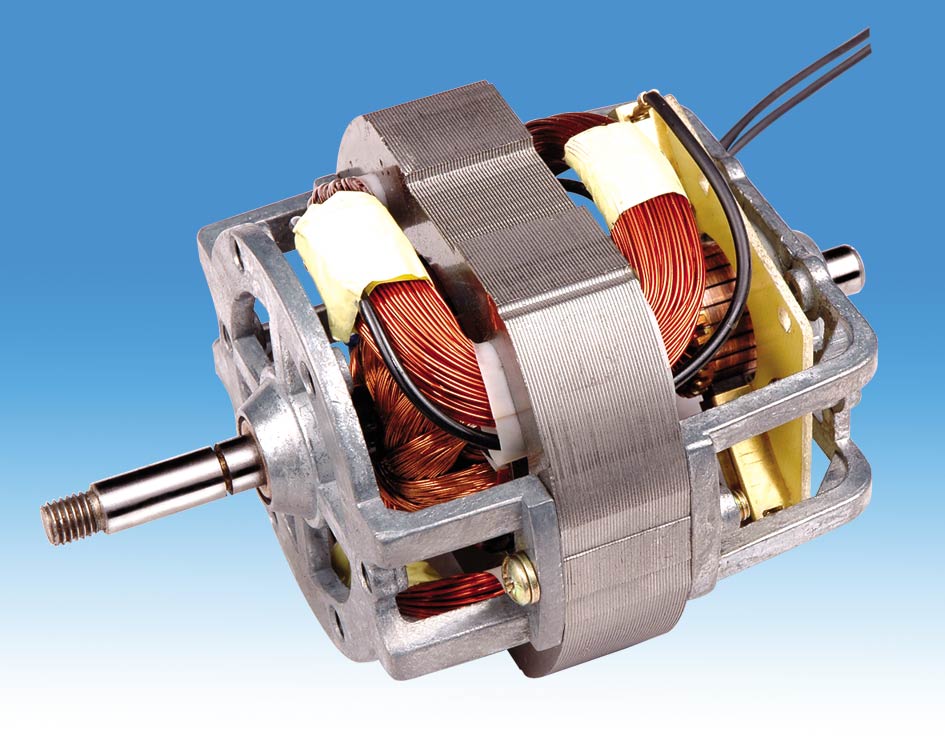

As a DIY project , i decided to make a system that controls the speed of a motor that work in both currents AC & DC ( a universal motor ).

For that i need to power the system with a 220 V AC supply , then i want to control the motor's speed with a 6 positions switch and not with a microcontroller or a potentiometer.

I find a lot of schematics on the net but i don't understand how they vary the speed of the motor .

I hope i explained very well my goal .

Thanks in advance .

As a DIY project , i decided to make a system that controls the speed of a motor that work in both currents AC & DC ( a universal motor ).

For that i need to power the system with a 220 V AC supply , then i want to control the motor's speed with a 6 positions switch and not with a microcontroller or a potentiometer.

I find a lot of schematics on the net but i don't understand how they vary the speed of the motor .

I hope i explained very well my goal .

Thanks in advance .