KansaiRobot

Member

Hello and thank you always.

Lately I have become interested in touch panels, and I am thinking of doing something related with this and PIC microprocessors.

However my knowledge of these is still very poor so I would appreciate some advice.

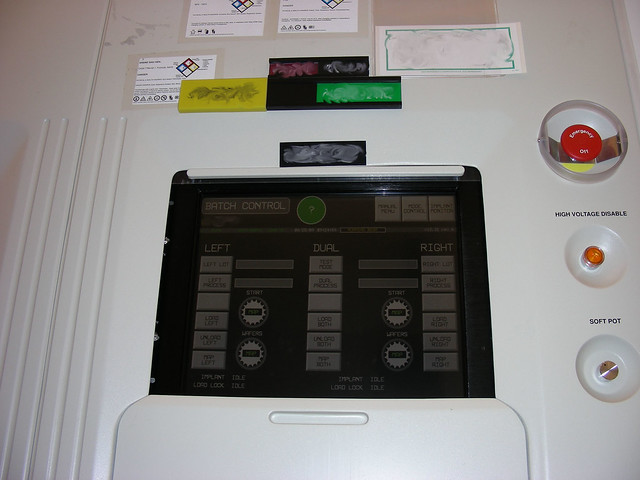

First, I have made some browsing and notice that there are either small (2.8, 3.5 , at most 7 inches) panels that can be controlled with say AVR micros or PICs, or there are big industrial solutions that I assume are completed products , so how can you integrate them to a more complex system...

Is my impression correct? If I were to require a medium size touch screen that I can use to do menu choosing and other finger commands, where can I find a list of available resources....

Thanks in advance for the help

Lately I have become interested in touch panels, and I am thinking of doing something related with this and PIC microprocessors.

However my knowledge of these is still very poor so I would appreciate some advice.

First, I have made some browsing and notice that there are either small (2.8, 3.5 , at most 7 inches) panels that can be controlled with say AVR micros or PICs, or there are big industrial solutions that I assume are completed products , so how can you integrate them to a more complex system...

Is my impression correct? If I were to require a medium size touch screen that I can use to do menu choosing and other finger commands, where can I find a list of available resources....

Thanks in advance for the help

)

)