gramo

New Member

Code:

Result = 0

Total = 0

X = 0

Repeat

DelaymS 1

Result = ADIN 0

Result = Result * 2

Total = Total + Result

Inc X

[B]Until X = 100[/B]

Total = Total / 15

Total = Total * 5 / 1023Change the number of samples too 100 like I did above, you could even go higher, but it will slow down your program. This should help smooth the Speedo

Leave 7.2 in this part, dont round it

Code:

Temp_Float = KMHT

Temp_Float = Temp_Float * 4 * 7.2

KMH = Temp_Float / 1000

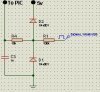

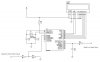

KMHT = KMHThe issue with the miss reading could be the impedance is too high for the ADC circuitry in the PIC. The datasheet specifies 2.5K Max impedance. This is to allow the internal capacitors on the PIC to charge and discharge properly, try use 2.2K resistors on the voltage divider.

Let me know if that helps