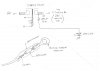

Automotive, compound-wound, segmented-commutator, 12V DC, starter motor, the kind with a Bendix drive, not the kind that uses a solenoid to engage to the ring gear.

If the Bendix fails stuck in, and the starter is back-driven by the engine after it starts, does the starter motor produce any open-circuit voltage (as a generator)?

Since there no current can flow back to the battery because I'm assuming that the starter relay released, there might be no path for field current to flow, so does that mean to act as a generator, there would have to be some residual magnetization of the pole pieces?

I'm trying to determine if there is a reliable way of knowing that the Bendix stuck.

If the Bendix fails stuck in, and the starter is back-driven by the engine after it starts, does the starter motor produce any open-circuit voltage (as a generator)?

Since there no current can flow back to the battery because I'm assuming that the starter relay released, there might be no path for field current to flow, so does that mean to act as a generator, there would have to be some residual magnetization of the pole pieces?

I'm trying to determine if there is a reliable way of knowing that the Bendix stuck.