Patman83

New Member

I need to make a footprint for SIP male/female headers. I realize that it is the simplest device you would ever have to make a footprint for, but I still had a question.

How big should I make the pads?

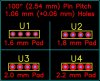

The software I am using makes it very easy to create or modify footprints. I could easily make a couple different ones for use in different situations, but I want to make one "general use" to put in my library. I am thinking 1.8mm - 2.0mm. I understand that different situations warrant different footprints - larger for high currents, stronger connections and smaller to allow for routing low current pathways between the pads. But what is a good, all around, in between size?

How big should I make the pads?

The software I am using makes it very easy to create or modify footprints. I could easily make a couple different ones for use in different situations, but I want to make one "general use" to put in my library. I am thinking 1.8mm - 2.0mm. I understand that different situations warrant different footprints - larger for high currents, stronger connections and smaller to allow for routing low current pathways between the pads. But what is a good, all around, in between size?