The stuff I use is made by MG-Chemicals the 1Kilo bottle product number is 410-1KG. For MG-Chemical distributors in Ontario seedasatboy said:Is there some where locally you can get this chemical like home hardware ext. I live in Ontario, Canada. Digikey does not seem to have it in there cataloge.

dasatboy said:It is a starter kit, PCB Fab-In-A-Box by a company called Pulsar. Has 20 Sheets TTS, a role of green TRF, White TRF, 2PCS 8"x10" double sided .032", 1/2oz copper boards and 2 same spec. 8"x10" single sided boards.

I didn't buy the laminator they suggest, most of the boards I plane to make are small and I figure I can use a close iron.

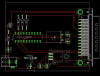

I did use a progie called "expressPCB and ExpressSCH" but when you print out the laters they are not mirrored for the board. I will try the eagle program.

Eagle works great. The Beta version is easier to use but it is a beta.

I use the pulsar system with very good results. There site has a tips section that tells how to use a wood dowel under the PCB to simulate a laminator with a iron.

Most of the boards I make are small. I have a laminator and would not go back to using an iron. But thats me and YMMV.

Make sure to set your laser printer to max dark. You transfer can only be as good as what the laser printer prints.

I would be happy to answer any questions on using the kit. It is one of my favorite subjects.

The pulsar site has good info.

The same paper can be used to make decals. I have the spray adhesive but have not tried it yet. You can do some neat stuff with this system.

For SS boards I spray the top with Krylon Fusion white. This makes a nice background for a toner transfer of the topside artwork (silkscreen). I coat the artwork with conformal or clear acrylic.

EDIT:

I use 3M brand blue painters tape to tape the TTS paper to the printer paper to print the image. And the same to tape the TTS to the PCB to transfer the image.

Last edited: