Mikebits

Well-Known Member

The single most largest revenue maker in the MCU market is automotive (I can't imagine the hobby market is even a blip on the sales chart). According to EE Times, the merger will position Microchip a dominant position in a market that is expected to grow well beyond 2017.

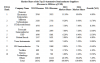

**broken link removed**Microchip Technology Inc.’s pending $3.8 billion acquisition of Atmel Corp. would move Microchip into the No. 3 position among microcontroller vendors less than two months after NXP Semiconductors NV moved into the No. 2 spot with the acquisition of Freescale Semiconductor Inc.

”We see a compelling financial and strategic rational to acquire Atmel,” said Steve Sanghi, Microchip’s chairman, president and CEO, in a conference call earlier this week. “ The combination of Microchip and Atmel will create an MCU powerhouse and move Microchip from the No. 4 to the No. 3 position in microcontrollers based on the most recent Gartner marketshare data.”