hamholfarm

New Member

Hello,

TLDNR: Please identify the blown component in the pics – provide specifications so a dummy can order a new one.

I apologize for the long post; I’m trying to provide as much information as possible to help identify the blown component.

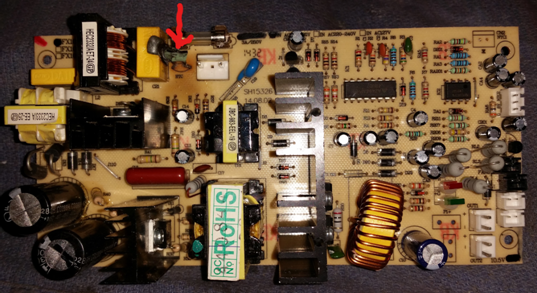

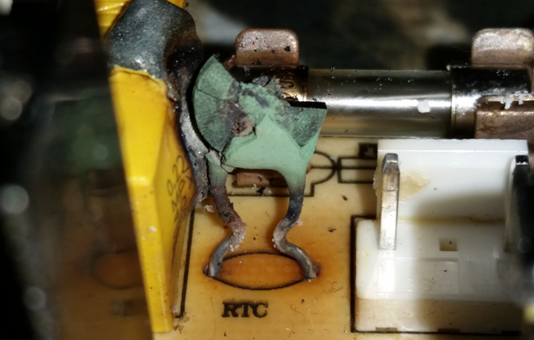

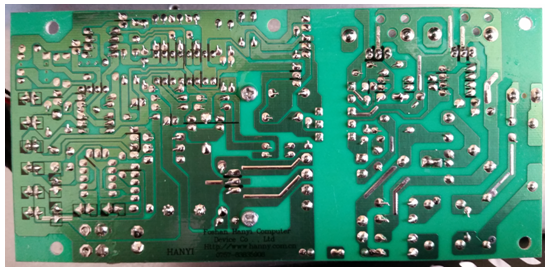

Please see the pics for the blown component needed, it is labeled on the board as RTC. The second blown component was easy to identify and replace (0.1 uF K 275VAC Tenta Safety Capacitor). The PC board is from a Wine Cooler/Refrigerator, Input voltage: 115 V/60 Hz, 140 Watts, 1.9 Amps. If you can identify what component is needed, please be specific so I am able to order a new one, a link would be very helpful.

The Wine Cooler is obsolete and there are no replacement boards to be had. The distributor could not provide any additional information. Two E-mails to the website printed on the PC board have gone unanswered.

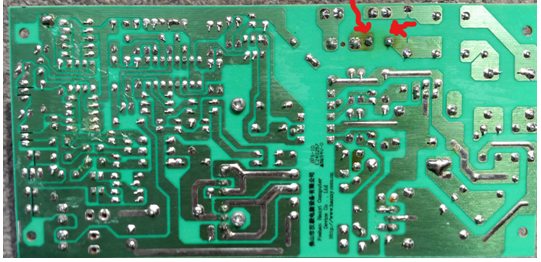

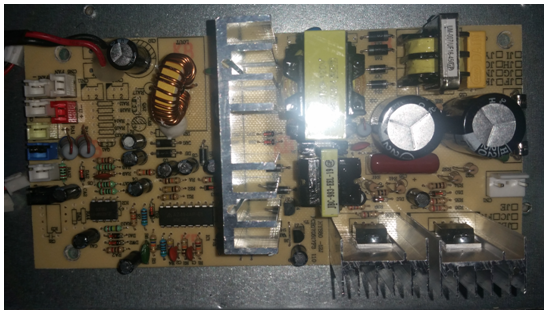

The second set of pics is from a newer model Wine Cooler/Refrigerator. The PC board is from the same manufacturer. Since the one component is the same (Tenta Safety Capacitor), I was thinking if the manufacturer was trying to save costs and additional SKU’s; maybe the blown component is the same as the one used in this board?

Could this be the same as the blown component in the first set of pics?

If I can provide any additional information, please let me know.

Thank you!

TLDNR: Please identify the blown component in the pics – provide specifications so a dummy can order a new one.

I apologize for the long post; I’m trying to provide as much information as possible to help identify the blown component.

Please see the pics for the blown component needed, it is labeled on the board as RTC. The second blown component was easy to identify and replace (0.1 uF K 275VAC Tenta Safety Capacitor). The PC board is from a Wine Cooler/Refrigerator, Input voltage: 115 V/60 Hz, 140 Watts, 1.9 Amps. If you can identify what component is needed, please be specific so I am able to order a new one, a link would be very helpful.

The Wine Cooler is obsolete and there are no replacement boards to be had. The distributor could not provide any additional information. Two E-mails to the website printed on the PC board have gone unanswered.

The second set of pics is from a newer model Wine Cooler/Refrigerator. The PC board is from the same manufacturer. Since the one component is the same (Tenta Safety Capacitor), I was thinking if the manufacturer was trying to save costs and additional SKU’s; maybe the blown component is the same as the one used in this board?

Could this be the same as the blown component in the first set of pics?

If I can provide any additional information, please let me know.

Thank you!