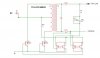

Exactly! Once you know the basics its just a matter of a few added details to make almost any stand alone inverter system grid tie capable with in reason.

Add the proper synchronizing circuits, some basic safety interlocks, and some filters if needed and thats really about all there is to it.

Add the proper synchronizing circuits, some basic safety interlocks, and some filters if needed and thats really about all there is to it.