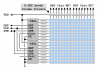

I have completed a 16x16 LED matrix scrolling clock display on a $10 Parallax SX52 Protoboard and micro-controller. It uses a DS1302 Real Time Clock and 32KHz crystal for accurate stability in keeping track of the time and date. This is all working well as you can see in my attachment zip. Also here is an older version of the design from YouTube.com:

https://www.youtube.com/watch?v=HtUVlkJdNwM

Here is my new challenge:

I have recently purchased some 8x8 LED modules on Ebay that are bi-color. This means for my 16x16 LED display, I would have 4 modules giving me 16 row anodes (which I use transitor/resistor drivers) and 16 rows of cathodes (which I use ULN2803 drivers) of either RED or GREEN LEDs (which really mean I have 32 cathode lines of collumns) to my SX52 microcontroller (all programmed in SX/B - SX Basic with an interrupt routine). However, since this microcontroller currently uses RD and RE for the 16 rows of cathodes and RB and RC for the 16 columns of anodes (as well as 3 interface lines of RA for the DS1302), I only have 5 additional I/O lines (RA.3 - RA.7) left. I need 16 additional lines of column cathode output I/O lines for the bi-colored LEDs.

Is there any circuitry available that can take the 16 output lines from RB and RC and switch them into 2 banks of 16 output lines (32 total outputs) that are controlled through something like an enable line (e.g. 0 = turn first bank on for green LEDs, 1= turn 2nd bank on for red LEDs). However, the ideal situation is to have 32 I/O outputs where I only have 16 currently for the collumns. The reason is that I would like to have it running fast enough to appear that both red or green individual LEDs could be on and not just one or the other. The enable line might be controlled via an unused RA I/O line on the SX52.

I realize that many of you may not be familliar with the Parallax SX line of micro-controllers (but in this case I am concerned more on the hardware external circuitry) and you can think of the SX52 is more or less a PIC chip (which I am only vaguely familiar with PIC chips).

Any ideas on what chips should be used to do this?

https://www.youtube.com/watch?v=HtUVlkJdNwM

Here is my new challenge:

I have recently purchased some 8x8 LED modules on Ebay that are bi-color. This means for my 16x16 LED display, I would have 4 modules giving me 16 row anodes (which I use transitor/resistor drivers) and 16 rows of cathodes (which I use ULN2803 drivers) of either RED or GREEN LEDs (which really mean I have 32 cathode lines of collumns) to my SX52 microcontroller (all programmed in SX/B - SX Basic with an interrupt routine). However, since this microcontroller currently uses RD and RE for the 16 rows of cathodes and RB and RC for the 16 columns of anodes (as well as 3 interface lines of RA for the DS1302), I only have 5 additional I/O lines (RA.3 - RA.7) left. I need 16 additional lines of column cathode output I/O lines for the bi-colored LEDs.

Is there any circuitry available that can take the 16 output lines from RB and RC and switch them into 2 banks of 16 output lines (32 total outputs) that are controlled through something like an enable line (e.g. 0 = turn first bank on for green LEDs, 1= turn 2nd bank on for red LEDs). However, the ideal situation is to have 32 I/O outputs where I only have 16 currently for the collumns. The reason is that I would like to have it running fast enough to appear that both red or green individual LEDs could be on and not just one or the other. The enable line might be controlled via an unused RA I/O line on the SX52.

I realize that many of you may not be familliar with the Parallax SX line of micro-controllers (but in this case I am concerned more on the hardware external circuitry) and you can think of the SX52 is more or less a PIC chip (which I am only vaguely familiar with PIC chips).

Any ideas on what chips should be used to do this?

Attachments

Last edited: