markelectro

New Member

Hello to all

I have a Gent master clock that has 30 sec impulsing. This gives an impulse to slaves 2 x per minuet.

The 30 sec pulse you will see from the link is obtained from a wheel that has 30 teeth , one of the teeth is longer than the rest causing the pendulum to knock the rest from the impulse arm thus causing a pulse.

**broken link removed**

I have a 1 sec polarising slave that I would like to run from the master clock, unfortunately this clock does not have 1 sec pulses to the slaves. the slave does require a pulse length of around 0.7 sec for it to work and is 24v 3000 ohms

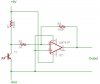

I was thinking of an electro circuit that could maybe wired into the wiring of the clock that would give out 1 sec AC. pulses. Or sensors that could watch the 30 toothed count wheel and at each tooth a pulse is triggered.

What ever way we arrive at it must be governed by the clocks pendulum and not an external circuit like a crystal oscillator.

I do have clocks that use reed switches in other clock but I think this one needs to be different.

I do have a PIC. programmer but at the moment I don't have the asm. knowledge.

I would welcome any thoughts and advice.

Regards Mark

I have a Gent master clock that has 30 sec impulsing. This gives an impulse to slaves 2 x per minuet.

The 30 sec pulse you will see from the link is obtained from a wheel that has 30 teeth , one of the teeth is longer than the rest causing the pendulum to knock the rest from the impulse arm thus causing a pulse.

**broken link removed**

I have a 1 sec polarising slave that I would like to run from the master clock, unfortunately this clock does not have 1 sec pulses to the slaves. the slave does require a pulse length of around 0.7 sec for it to work and is 24v 3000 ohms

I was thinking of an electro circuit that could maybe wired into the wiring of the clock that would give out 1 sec AC. pulses. Or sensors that could watch the 30 toothed count wheel and at each tooth a pulse is triggered.

What ever way we arrive at it must be governed by the clocks pendulum and not an external circuit like a crystal oscillator.

I do have clocks that use reed switches in other clock but I think this one needs to be different.

I do have a PIC. programmer but at the moment I don't have the asm. knowledge.

I would welcome any thoughts and advice.

Regards Mark

Last edited: